Punching and shaping technique – diversity in form and function

The individual moulded parts, manufactured by BAUMGARTEN, offer the highest precision standard, guarantee faultless functioning and ensure the highest safety level.

By request the punched, drawn or pressed shaped parts can be degreased, galvanised with zinc or be painted.

Our engineering and toolmaking departments are of an particular advantage to you. Experienced specialists offer you competent assistance already during product development and work out the most economically advantageous manufacturing method of the planned moulding.

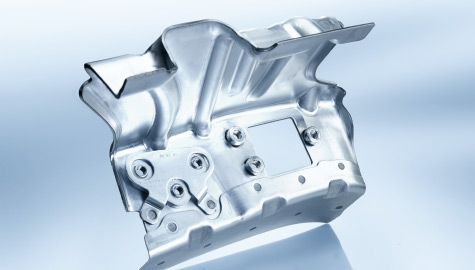

FORMED PARTS

Node part

High degree of forming in the edge area

500 × 350 mm

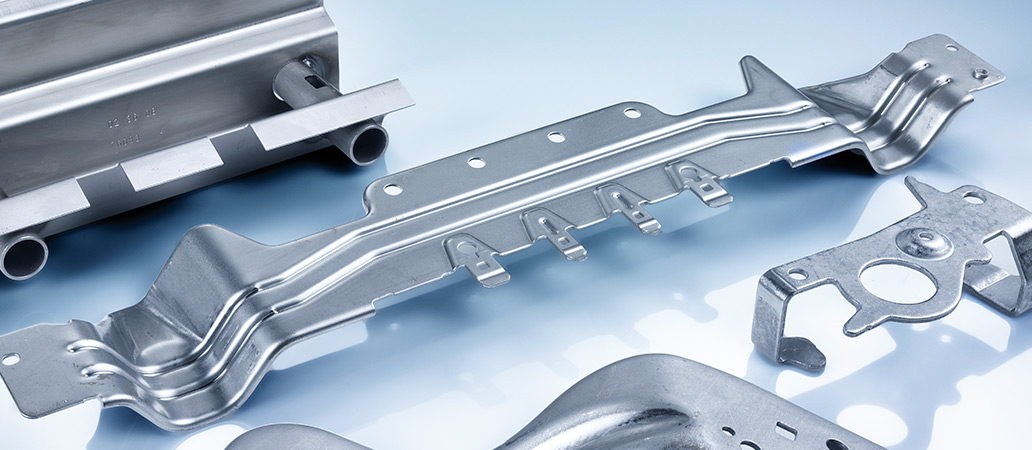

Fitting parts for seat adjustment

High precision requirement

Seat side part

High-strength grade of steel with embossment, flanged rim and high precision requirements at the rim hole (when drawing through)

Pivot bearing sheet

High strength of material with high precision requirements, perforations in different planes