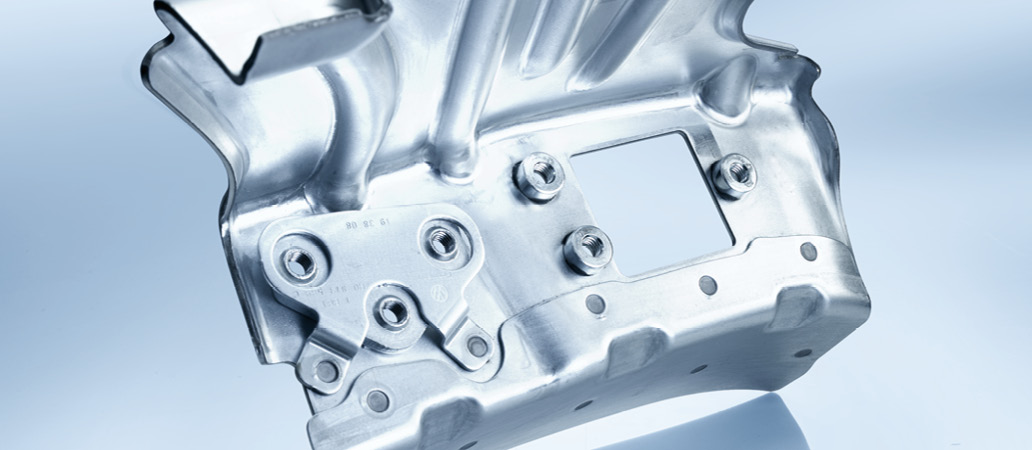

Welded assemblies

In different fusion and pressure welding processes BAUMGARTEN joins metal parts reliably together to a unit

WE OFFER YOU

Modern equipped assembly department

Employees with a very strong sense of responsibility

Practice-oriented organisation

Just in time

ADVANTAGES

Everything from one source

Fast decision-making processes

High flexibility

ASSEMBLIES

Hinge reinforcement

Made from 5 constructional parts galvanised with zinc, spot-welded (11 spots), with extruded holes

Seat height adjustment

Made from 5 different forming components, inert gas and projection welding, with extruded holes, riveted and painted

Assembly

Made from different punched and bent wire parts, riveted and spot-welded

Headrest plate

Made from 1 mm thick sheet steel, inert gas welded pipes with high demands on parallelism